PLW 7111 [Safety S-1011]

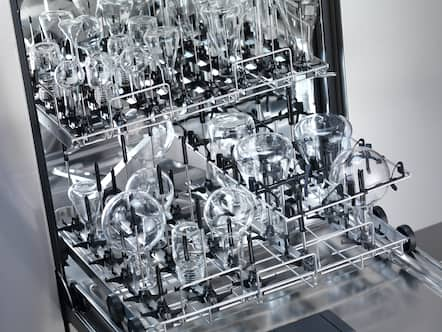

Washer-disinfector for the reprocessing of breathing apparatus – SlimLine, electric heating, drying, drain pump and condenser.

- Alternative performance/cycle 2 compressed air bottles

- Alternative performance/cycle 2 compressed air unit carrier frames

- Flexible for loading with a usable capacity of 241 l litres

- Intuitive operation and programmable controlsIntuitive and flexible

7" full-touch colour display for intuitive and convenient use and simple process control. Flush-fit display in machine front for simple and safe cleaning. Programmes are flexible and can be modified to suit individual needs. - High-performance system and specific programmesPowerful and reliable

In combination with the programmes that have been adapted specifically for the breathing apparatus, the high-performance washer system delivers efficient reprocessing and reliable results.

EAN 4002516669326 / Article number 62711134GB / Material number 12278760

| Construction type | Freestanding, 1 glazed hinged door Full-glass door In combination with the chamber lighting, the glass door allows a visual check of the current process. |

|---|---|

| Type of heating | Electricity |

| Front/back | Stainless Steel |

| Side panels | Stainless steel |

| Single/multiple installations | |

| Slimline construction type | |

| Number of wash levels | 2 |

| Loading and unloading with telescopic runners | |

| Electric door lock | |

| Buzzer, acoustic signal at end of programme | |

| Service-friendly design |

| Suitable for fire brigades and rescue services |

|---|

| Breathing masks [number] | 16 |

|---|---|

| Compressed air bottles [number] | 2 |

| Compressed air unit carrier frames with compressed air bottle [number] | 1 |

| Compressed air unit carrier frames [number] | 2 |

| Circulation pump, Qmax in l/min | 750 |

|---|---|

| Wash cabinet usable capacity in l | 241 |

| Electrical connection | 3N AC 380-415V 50HZ |

|---|---|

| Heater rating in kW | 8.4 |

| Total rated load in kW | 10.1 |

| Fuse rating in A | 16 |

| Length of mains connection cable in m | 4 |

| Cold water [number] | 1 |

|---|---|

| Hot water [number] Efficient hot water connection Connection to the warm water supply saves a lot of time and energy. | 1 |

| DI water [number] DI water connection Thanks to the connection for fully demineralised water (DI water), these washer-disinfectors and thermal disinfectors facilitate optimum reprocessing results. Carrying out the final rinse with DI water also protects valuable wash items from deposits and corrosion. | 1 |

| Required flow pressure in kPa | 100-600 |

| Maximum water hardness (cold water/hot water) in mmol/l | 0.7 |

| Drain pump [DN] | 25 |

| Drain valve [DN] | 38 |

| Water protection system |

| Drying unit heating type | Electricity |

|---|---|

| Air throughput in m³/h | 130 |

| Time setting in 1-minute increments | 0-60 |

| HEPA filter class | H14 |

| HEPA filter filtration efficiency (DIN EN 1822) in % | 99.995 |

| Electric heater rating in kW | 4 |

| External dimensions, net height in mm | 702 |

|---|---|

| External dimensions, net width in mm | 650 |

| External dimensions, net depth in mm | 1965 |

| External dimensions, gross height in mm Note Including packaging | 2110 |

| External dimensions, gross width in mm Note Including packaging | 945 |

| External dimensions, gross depth in mm Note Including packaging | 840 |

| Wash cabinet, height in mm | 717 |

| Wash cabinet, width in mm | 570 |

| Wash cabinet, depth in mm | 590 |

| Rack height above floor in mm | 850 |

| Net weight in kg | 251 |

| Gross weight in kg Note Including packaging | 260 |

| Maximum floor load in N/m² Maximum floor bearing capacity Maximum floor bearing capacity states the maximum weight (N) that can be placed on the supporting surface on which the machine is installed. This maximum load bearing capacity is the result of adding up the weight of the machine, the load and the water in it, as well as the dynamic forces that occur during operation. | 680 |

| Sound pressure LpA in cleaning and drying according to DIN EN ISO 11201 Emissions - sound pressure at workplace The emission sound pressure level depends on the programme and is a value given to the noise created by the machine. Miele Professional appliances have very low noise levels. | 68 dB(A) re 20 µPa |

|---|---|

| Heat dissipation into the room in MJ/h Heat output into the room During operation warm air is vented into the surrounding room. The released amount of heat/time depends on the set temperatures and the intensity of use. The stated maximum value can be used to control the temperature of the area or to calculate an increase in room temperature. | 0.8 |

| Breathing apparatus | |

|---|---|

| Vario FB Special | |

| Vario FB Special Plus | |

| Vario FB Chem | |

| Vario FB Chem Plus | |

| Drying FB |

| 2 integrated diaphragm dispenser pumps for liquid media | |

|---|---|

| Additional integrated dispenser pumps | 2 |

| Steam condenser (optional) | |

| Volume flow control | |

| Interface for process documentation | |

| Multi-component filter system | |

| Load carrier – direct coupling | |

| Integrated hot air drying | |

| Miele Cloud Service | |

| Setting options for process chemicals (3 x 5 l) | |

| Wash cabinet made of high-quality stainless steel (1.4404/316L), electropolished | |

| SlimLine mobile plinth | |

| Variable-speed pump | |

| Multi-coloured chamber lighting | |

| Modular basket design |

| CE | |

|---|---|

| EN 61010-1 | |

| EN 61010-2-040 | |

| RoHS guideline 2011/65/EU | |

| Machinery Directive 2006/42/EC |

Additional accessories and consumables

Find additional accessories and consumables to go with this product

Find here the accessories that can be bought additionally for this product.