PWD 8682 [DC5]

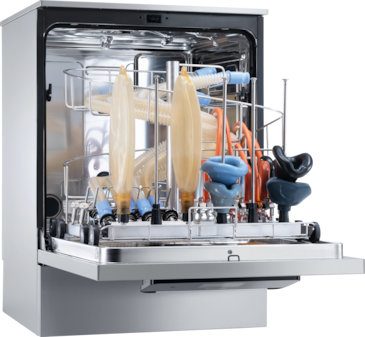

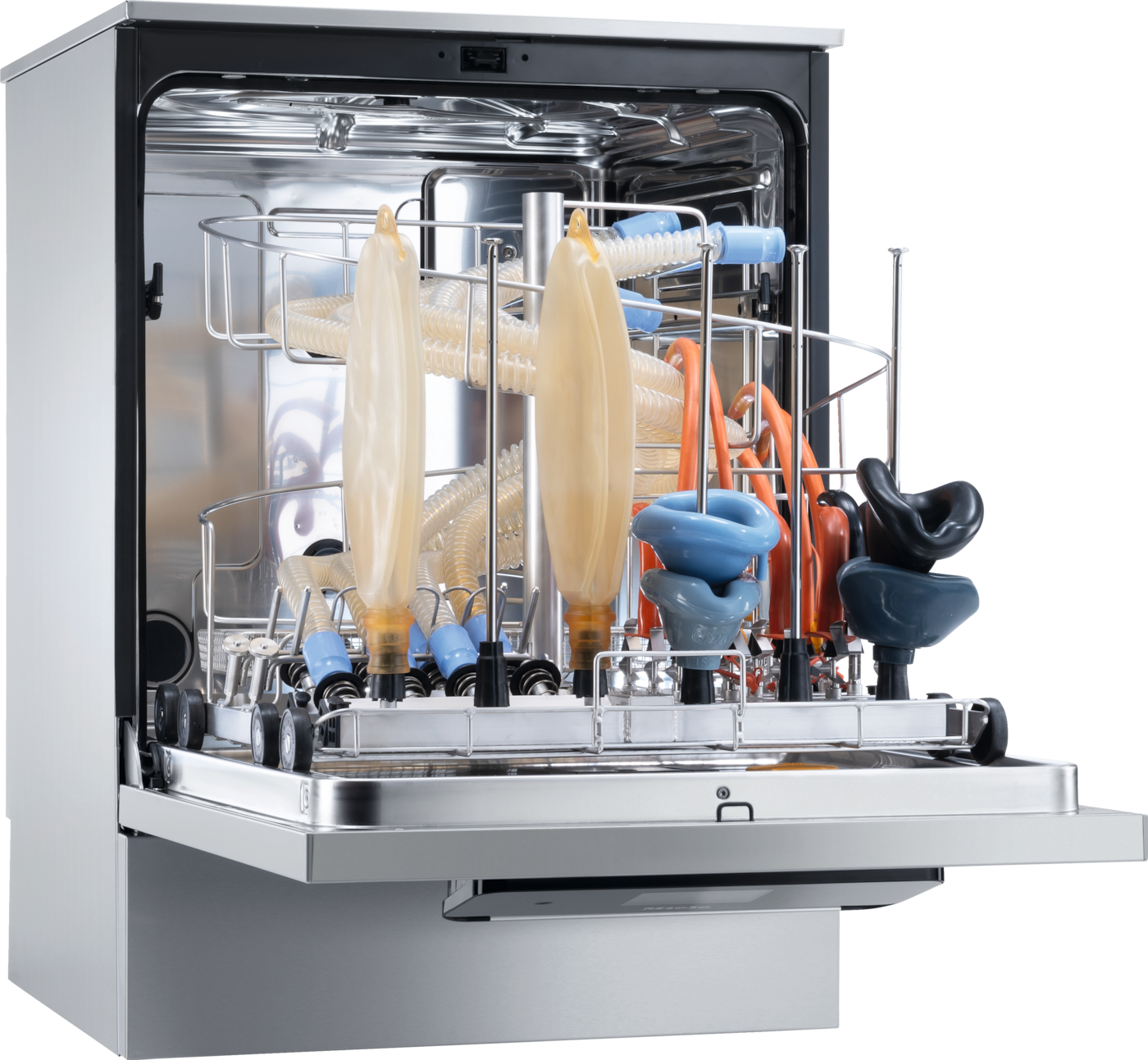

Thermal disinfector and washer-disinfector with AD water connection, liquid dispensing & EcoDry function.

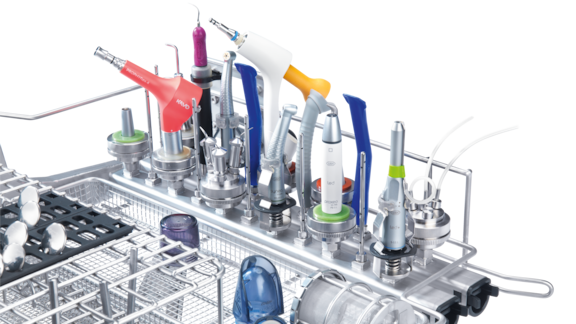

- Perf./cycle, e.g. 44 transmission instruments or 44suction devicesFurther stacking options

Further instruments can be also be reprocessed in the upper or lower basket in each cycle. - Throughput/cycle e.g. 8 DIN mesh trays or 48GYN speculaFurther stacking options

Alternatively, 2-3 AN sets can be reprocessed per cycle. - Safety through monitoring - wash pressure and spray arm monitoringFor a reliable result

Outstanding preparation results are achieved because the jet pressure and spray arms are monitored continuously and a decline in jet pressure or load blockage is detected immediately - Maximum user convenience with M Touch Flex full-touch colour displayM Touch Flex controls

Use all dishwashing programmes and machine functions conveniently with a touch of a fingertip on the clear text touch display. - Convenient drying support - EcoDryUnique

At the end of the reprocessing programme the machine door opens automatically as soon as the temperature in the wash cabinet has fallen below 70 °C, thanks to the AutoOpen function. This allows residual moisture to escape easily from the wash cabinet and the washed items to dry more quickly. - Connectivity as standard via WiFiComplete documentation

The machine is delivered with a WiFi communication module as standard, which is able to establish a secure state-of-the-art network connection. The module supports the connection of compatible process documentation software solutions and network printers.

EAN 4002516883678 / Article number 62868206NWE / Material number 12798430

| Construction type | Freestanding, can be built-under, slimline |

|---|---|

| Range | ExpertLine |

| Casing | Stainless steel |

| Control panel colour | Black |

| Lid | Stainless Steel |

| Can be built-under | |

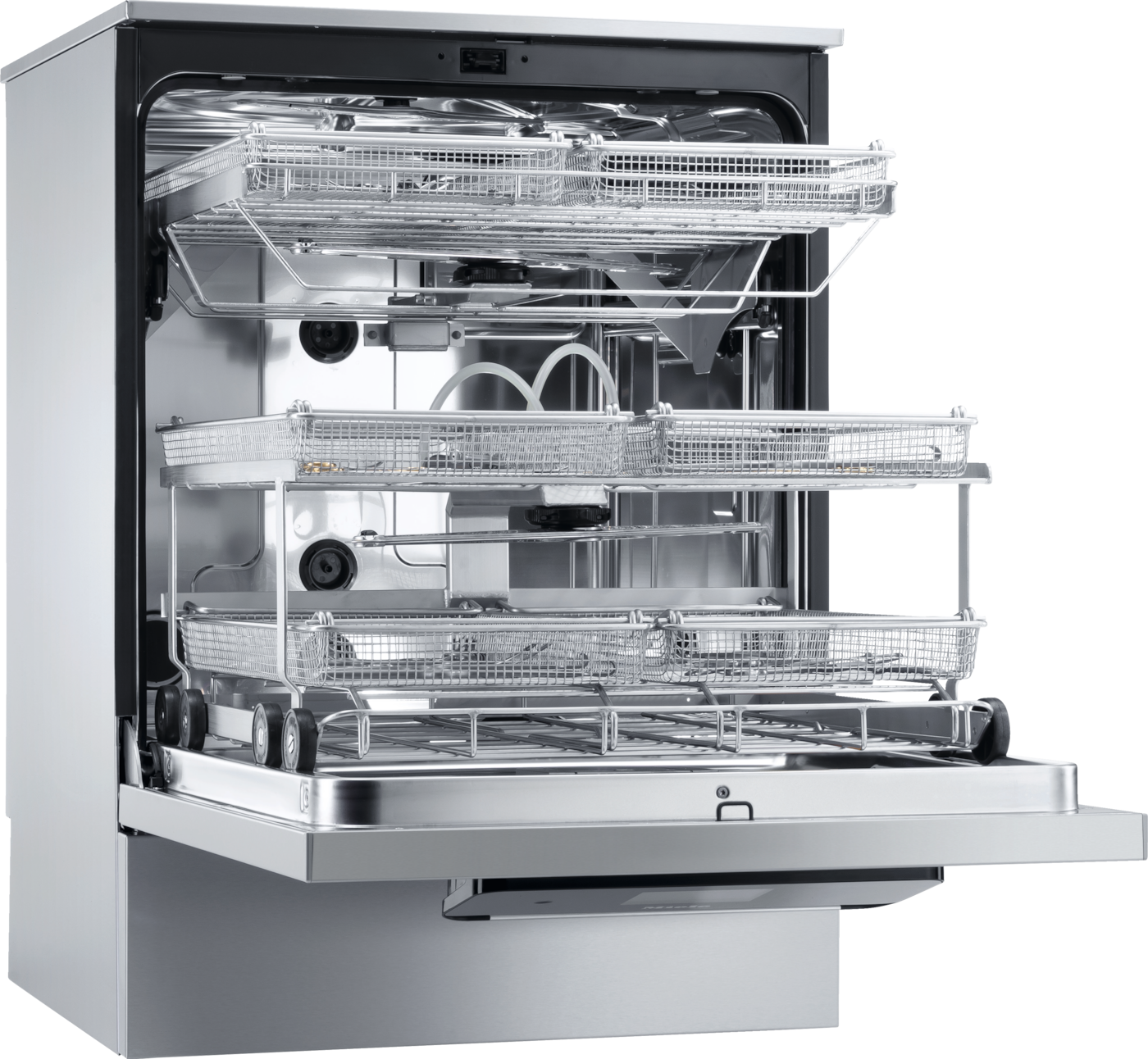

| Number of wash levels | 2 |

| AutoClose – automatic door lock | AutoClose2 A light touch is all it takes: With AutoClose, the door closes by itself. |

| Buzzer, acoustic signal at end of programme | |

| Service-friendly design |

| DIN mesh trays per cycle [number] | 8 |

|---|---|

| GYN specula per cycle [number] | 48 |

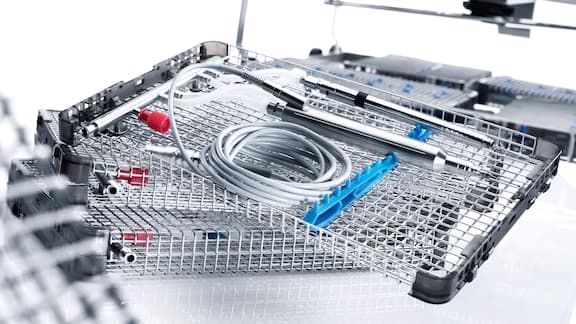

| MIS sets per cycle [number] | 1-2 |

| Ophthalmology sets per cycle [number] | 8 |

| AN sets per cycle [number] | 2-3 |

| Theatre shoes per cycle [number] | 28 |

| Surgical saliva extractors per cycle [number] | 44 |

| Lumened instruments per cycle [number] | 44 |

| Transmission instruments per cycle [number] | 44 |

| Circulation pump, Qmax in l/min | 500 |

|---|---|

| Shortest programme running time (cleaning and disinfection) in min Drying Some machines have a drying option. This can be set individually depending on the reprocessing situation. | 40 |

| Shortest programme running time (cleaning and disinfection) in min Drying Some machines have a drying option. This can be set individually depending on the reprocessing situation. | 19 |

| Maximum final rinse temperature in °C | 93 |

| Wash cabinet usable capacity in l | 145 |

| Tested operating hours Note Our machines undergo intensive testing under laboratory conditions. The actual operating hours may vary depending on actual usage behaviour, maintenance and care of the machine. | 15000 |

| Miele MOVE Connect (option) | |

|---|---|

| Miele MOVE MedDent+ (option) |

| Electrical connection | 3N AC 400V 50HZ |

|---|---|

| Electric heater rating in kW | 8.5 |

| Total rated load in kW | 9.3 |

| Fuse rating in A | 16 |

| Length of mains connection cable in m Note The length refers to the supply lead on the outside of the appliance. | 1.9 |

| Electrical connection | AC 230V 50HZ |

|---|---|

| Electric heater rating in kW | 2.5 |

| Total rated load in kW | 3.3 |

| Fuse rating in A | 16 |

| Cold water [number] | 1 |

|---|---|

| Hot water [number] Efficient hot water connection Connection to the warm water supply saves a lot of time and energy. | 1 |

| DI water [number] DI water connection Thanks to the connection for fully demineralised water (DI water), these washer-disinfectors and thermal disinfectors facilitate optimum reprocessing results. Carrying out the final rinse with DI water also protects valuable wash items from deposits and corrosion. | 1 |

| VEP feed pump for demineralised water (option) | |

| Required flow pressure in kPa Note on ADP variants This value applies to cold, hot and DI water; however, it does not apply to DI water intake on ADP variants because these use a feed pump. | 200-1000 |

| Maximum delivery head for drain pump in cm | 100 |

| Integrated water softener | |

| Maximum water hardness (cold water/hot water) in mmol/l | 10.7 |

| Drain pump [DN] | 22 |

| Water protection system Waterproof System (WPS) Protection against flooding: In the event of problems, the system stops water intake automatically. | Waterproof system |

| External dimensions, net height in mm | 835 |

|---|---|

| External dimensions, net width in mm | 598 |

| External dimensions, net depth in mm | 598 |

| External dimensions, gross height in mm Note Including packaging | 920 |

| External dimensions, gross width in mm Note Including packaging | 670 |

| External dimensions, gross depth in mm Note Including packaging | 740 |

| Wash cabinet, usable height in mm | 520 |

| Wash cabinet, usable width in mm | 530 |

| Wash cabinet, depth of upper basket in mm | 474 |

| Wash cabinet, depth of lower basket in mm | 520 |

| Net weight in kg | 72 |

| Gross weight in kg Note Including packaging | 79 |

| Maximum floor load in N/m² Maximum floor bearing capacity Maximum floor bearing capacity states the maximum weight (N) that can be placed on the supporting surface on which the machine is installed. This maximum load bearing capacity is the result of adding up the weight of the machine, the load and the water in it, as well as the dynamic forces that occur during operation. | 1220 |

| Emission sound pressure level in the workplace Emissions - sound pressure at workplace The emission sound pressure level depends on the programme and is a value given to the noise created by the machine. Miele Professional appliances have very low noise levels. | <lt/>70 dB(A) re 20 µPa |

|---|---|

| Heat dissipation into the room in MJ/h Heat output into the room During operation warm air is vented into the surrounding room. The released amount of heat/time depends on the set temperatures and the intensity of use. The stated maximum value can be used to control the temperature of the area or to calculate an increase in room temperature. | 5.4 |

| Vario TD Intensive | |

|---|---|

| Vario TD Dental | |

| Vario Dental + | |

| Vario TD Instr 4 mesh trays | |

| Vario TD Instr 6 mesh trays | |

| Vario TD Instr 8 mesh trays | |

| Vario TD Container | |

| Vario TD AN | |

| Vario TD MIS | |

| Vario TD GYN | |

| Vario TD ENT | |

| Vario TD ENT + | |

| Vario TD ENT Optics | |

| Ophthalmology | |

| Ophtha tray A 207 | |

| Baby bottles | |

| Theatre shoes | |

| Ward utensils | |

| Universal | |

| Cold water rinse |

| 1 door dispenser for rinsing agent | |

|---|---|

| 1 dispenser pump for liquid cleaning agent | |

| 1 dispenser pump for neutralising agent | |

| Suction lance for media canisters 10–20 l (optional) | |

| Convenient suction lance DC5 | |

| Volume flow control | |

| Steam condenser | |

| Spray pressure monitoring | |

| Spray arm monitoring | |

| How-to sequences | |

| Chamber lighting | |

| Interface for process documentation (optional) | |

| Multi-component filter system | |

| Variable-speed heater pump | The heart of perfect results In the individual programmes the speed of the pump and thus the wash pressure is adjusted in line with the relevant requirements – high pressure facilitates the removal of stubborn soiling, whilst low pressure guarantees the complete wetting of all the wash items. As a result, the consumption of water and energy remains particularly low with optimum wash pressure at all times. |

| Load carrier – direct coupling | |

| EcoDry | EcoDry via patented AutoOpen function1 Quick drying: At the end of the reprocessing programme the appliance door opens automatically. |

| In-door salt container | |

| Customer Service optical interface | |

| Wash cabinet seamlessly welded using laser technology | |

| Heater elements outside wash cabinet | |

| Wash cabinet made from high-quality stainless steel (1.4301/304) | |

| Extensive components (option) |

| VDE (electrical safety) | |

|---|---|

| IP safety class according to EN 60529: IP 21 | |

| EN 61010-1 | |

| EN 61010-2-040 | |

| RoHS guideline 2011/65/EU | |

| EU medical device class IIb |

Additional components and consumables

Find additional components and consumables to go with this product

Find here the components that can be bought additionally for this product.

Find here the components that can be bought additionally for this product.

-

1.Patent: DE 102 007 008 950 B4

-

2.Patent: EP 1 733 675 B1